In industrial processing, the selection of double disc grinding machine models and specifications directly determines machining ac...

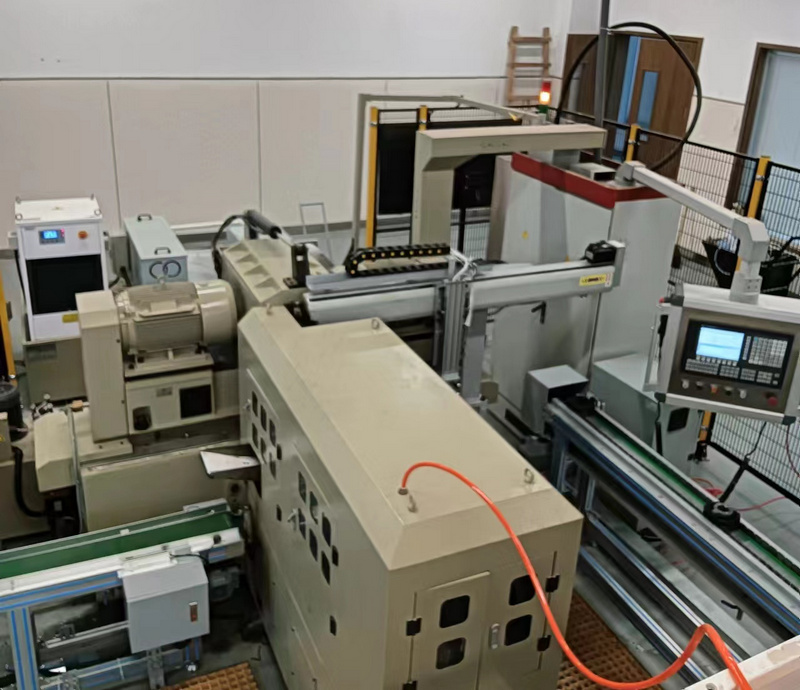

As the automotive manufacturing industry advances toward high precision and large-scale production, double disc grinding machines ...

As the “teeth” of grinding operations, the selection, installation, and maintenance condition of grinding wheels directly determin...

As a critical piece of equipment for achieving high-precision parallelism and dimensional consistency in workpieces, the adherence...

As critical equipment for high-precision machining, the long-term stable operation and machining accuracy of double disc grinding ...

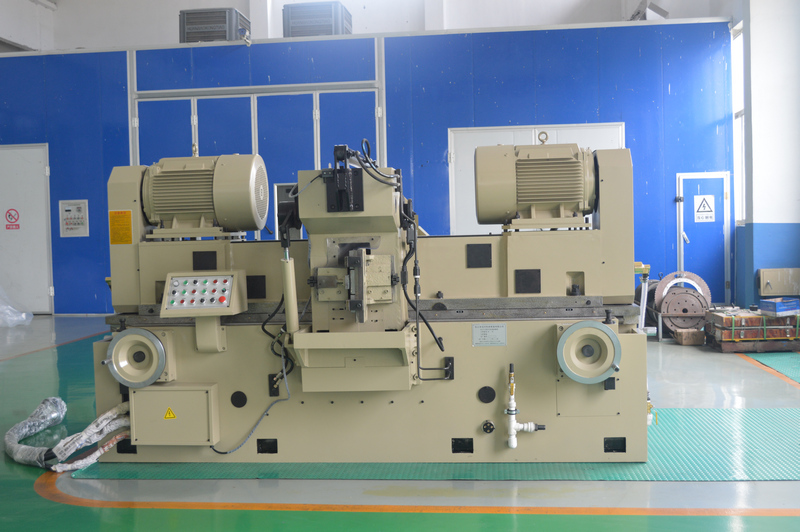

The core mission of a double disc grinding machine lies in simultaneously machining two parallel end faces of a workpiece with hig...

As a critical process for achieving high-precision parallelism and dimensional consistency, workpiece deformation during double di...

Selecting an appropriate double disc grinding machine is a critical decision directly impacting product quality, production effici...

The workflow of a double disc grinding machine constitutes a highly automated precision machining process designed to rapidly and ...

As high-precision machining equipment, stable operation of double disc grinding machines is fundamental to ensuring product qualit...

The machining quality of double disc grinding machines constitutes the core measure of their value. To achieve stable and high-pre...

In modern precision manufacturing, certain components impose exceptionally stringent requirements on the parallelism, flatness, an...