Amid the wave of smart manufacturing transformation, production equipment transcends mere processing tools to become core nodes ca...

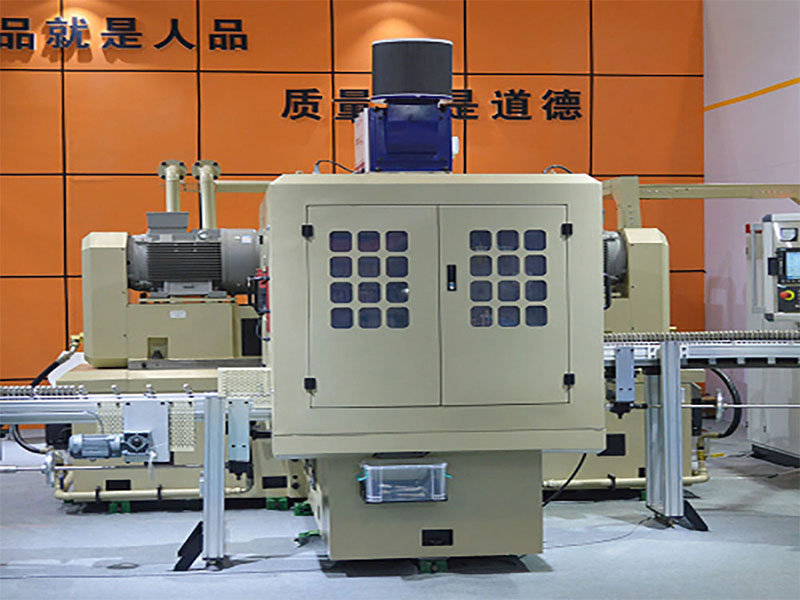

In modern engine connecting rod manufacturing processes, double disc grinding machines serve as critical equipment whose performan...

Traditionally, double disc grinding machines have been closely associated with metal component processing. However, with rapid tec...

In industrial applications, bearing reliability directly determines the performance and lifespan of mechanical equipment. The qual...

Historically, double disc grinding machines primarily served the automotive and bearing industries, processing conventional workpi...

Recent technological advancements in double disc grinding technology have closely aligned with production demands. Manufacturers a...

In mass production sectors like automotive components and bearing manufacturing, achieving both “high precision” and “high through...

In automotive parts production workshops, double disc grinding machines are the undisputed “precision champions.” From bearing rin...

As the “core equipment” for high-precision machining, choosing the right double disc grinding machine can double batch production ...

As high-precision machining equipment, double disc grinding machines operate with accuracy measured in micrometers. Neglecting rou...

The current precision machining industry faces the production challenges of accelerated product iteration, shrinking order batches...

In the precision grinding of difficult-to-machine materials such as ceramics, silicon carbide, and cemented carbide, “chipping, cr...