Manufacturing is undergoing a shift from “experience-driven” to “data-driven” practices, with double disc grinding machines playin...

In recent years, manufacturing demands for precision have continuously increased, particularly in new energy vehicles, hydraulic e...

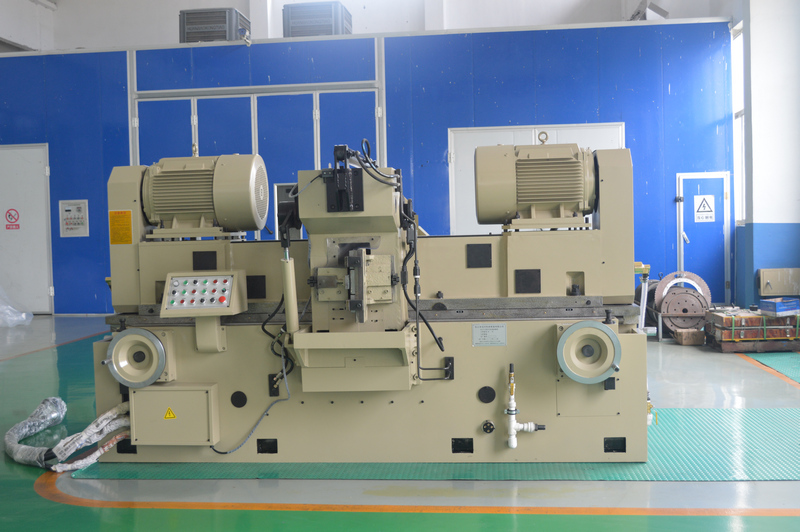

Many users new to double disc grinding machines often ask: “Is this equipment only useful in precision industries? Is it necessary...

In recent years, a clear trend has emerged in manufacturing—increasingly, factories are shifting from a “good enough” machining ph...

Over the past two years, both domestic and international manufacturing sectors have undergone a shared transformation: precision p...

As more factories transition toward automated and digital production, double disc grinding machines have emerged as a core compone...

Within the grinding industry, a common question arises: “Can single-end grinding machines with part flipping replace double disc g...

With the continuous growth of new energy vehicles, motor drive systems, and structural components for power batteries, the supply ...

In manufacturing, achieving consistency is more challenging than speed. The larger the batch size, the greater the risk of batch d...

As automation upgrades accelerate in manufacturing, many factories are transitioning from traditional processing methods to automa...

If you visit large manufacturing plants today, you'll notice a distinct shift: grinding machines that once operated independen...

In industrial-scale machining operations, the durability and efficiency of double disc grinding machines are pivotal factors deter...