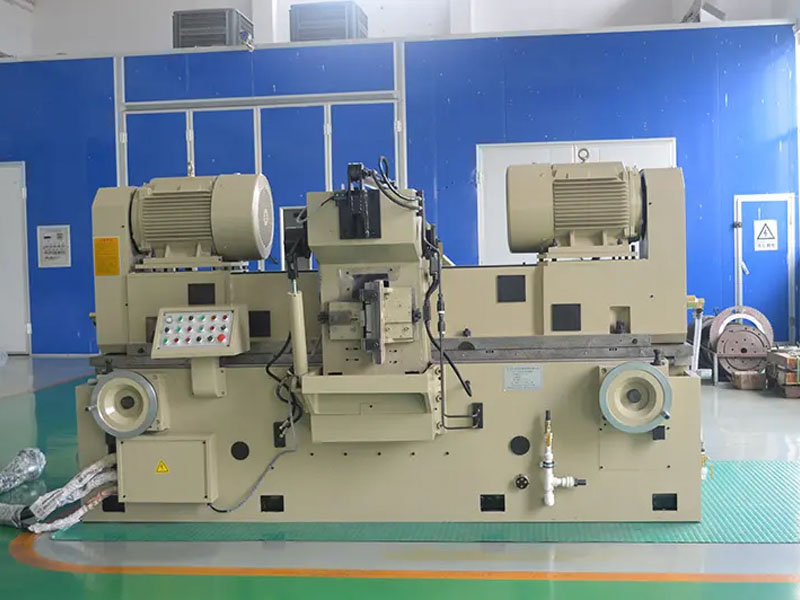

Before operating a double disc grinding machine, thoroughly inspect all components of the equipment. Check the power supply lines for any damage, ensure proper grounding, and verify that the electrical system connections are secure to prevent the risk of electrical leakage. Inspect the hydraulic and pneumatic lines for leaks and confirm that the pressure is within the specified range. Typically, the hydraulic system pressure should not exceed 6 MPa, while the pneumatic system pressure should be between 0.4 and 0.6 MPa. Grinding wheels must be carefully inspected for cracks or chips, and ensure they are securely installed. If any issues are found, they must be replaced to prevent fragmentation during operation.

Operators must wear personal protective equipment, including safety goggles, slip-resistant work shoes, and abrasion-resistant gloves. Long hair must be tied back and covered with a hat to prevent it from being caught in the equipment. Avoid wearing necklaces, bracelets, or other jewelry. Tuck in sleeves to prevent them from being caught by moving parts. Keep the work area clean and free of unnecessary items around the equipment to ensure clear pathways and prevent tripping.

When starting the equipment, follow the proper sequence: first turn on the main power supply, then activate the cooling and lubrication systems, and allow the equipment to run idle for 3-5 minutes. Observe whether the grinding wheel is running smoothly, and check for any abnormal sounds or vibrations. If any issues are detected, immediately shut down the machine for inspection, and only resume operation after the fault has been resolved. Do not feed material immediately after startup; wait until the equipment is running stably before beginning operations.

During operation, strictly prohibit touching the rotating grinding wheel or workpiece with your hands, and do not approach the grinding area to prevent injury from flying debris. When feeding material, ensure the workpiece is properly positioned and meets the requirements of the feeding mechanism to prevent tilting or jamming. If jamming occurs, stop the machine first and address the issue. Do not use tools to manipulate the workpiece while the machine is running to avoid danger.

During grinding, ensure the cooling system is functioning normally, and the coolant fully covers the grinding area to prevent the grinding wheel from overheating or the workpiece from being burned. If the coolant supply is insufficient, immediately stop the machine for inspection, replenish the coolant, or repair the piping. Simultaneously, monitor the grinding area; if abnormal sparks or unusual odors are detected, stop the machine promptly to investigate the cause.

When replacing the grinding wheel, first disconnect the power supply and wait until the grinding wheel has completely stopped rotating before proceeding. Use specialized tools for disassembly and installation; do not strike with hammers or other hard objects. Before installing a new grinding wheel, inspect it for cracks and use a balancing machine to perform balancing adjustments to ensure secure installation. After installation, run it idle for more than 5 minutes to confirm no abnormalities before starting grinding.

During equipment operation, cleaning or adjustment work is prohibited, and operation is not allowed with protective devices removed. Protective guards and other safety devices must remain intact to provide effective protection. In case of an emergency, immediately press the emergency stop button to cut off the power supply and prevent the accident from escalating.

After work is completed, first stop material feeding, wait until the last workpiece is processed, then shut off the grinding wheel motor, followed by the cooling system and lubrication system, and finally disconnect the main power supply. Clean debris and coolant from the equipment, wipe down the guideways and other areas to keep the equipment clean. Return tools and workpieces to their designated locations, maintain equipment usage records, and report any issues promptly for maintenance.