Grinding machines are staples in machining workshops, but not all grinders are the same. In particular, double disc grinders differ significantly from traditional single‑sided grinders in how they process parts and the results they produce. Understanding these differences helps in choosing the right equipment for your needs.

Traditional grinders typically work on one surface at a time. While sufficient for simple jobs, this approach can be less efficient and less accurate when parts require tight tolerances or parallel surfaces. Double disc grinders solve this by grinding both sides of a workpiece simultaneously, improving consistency and reducing cycle times.

One major advantage of double disc grinding is its precision. By synchronizing the grinding action on both surfaces, these machines minimize thickness variation and geometric errors, making them ideal for high‑precision components. This is especially useful in industries like automotive, aerospace, and precision manufacturing.

When selecting a grinder, analyze your production needs first. If your parts do not require extremely tight flatness or parallelism, a traditional grinder might suffice. However, for high‑volume production with stringent quality requirements, a double disc grinder offers clear benefits.

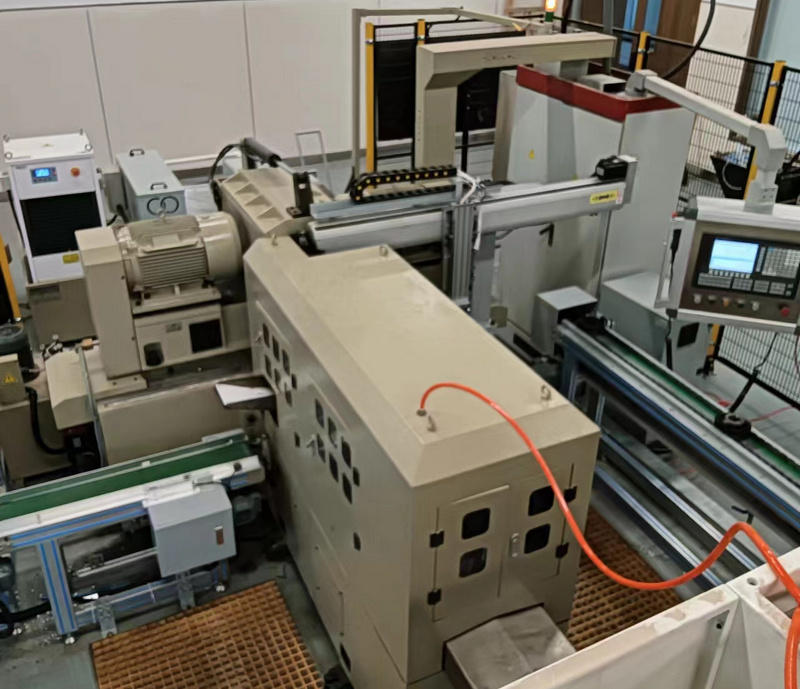

Many modern double disc grinders also include digital controls and automated features, which improve ease of use and reduce manual adjustments. This not only enhances processing stability but also reduces operator errors and downtime.

Finally, don’t overlook after‑sales support, spare parts availability, and maintenance services when choosing equipment. A machine that fits technically but lacks good support can increase long‑term costs. Comprehensive evaluation ensures you pick a grinder that delivers value over its full service life.